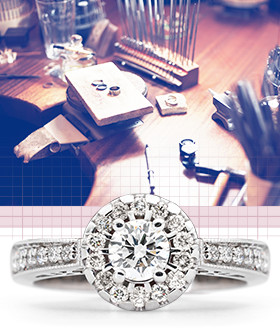

CRAFTSMANSHIP

Every nina’s design is crafted as a result of the ancient metal-working skills of the master jeweller combined with the latest computer-aided design and 3d printing technology. together, these techniques create magic out of the best quality raw materials, revealing objects of beauty and resilience that will stand the test of time.

Design

The jewellery design process is part inspiration and part engineering, all on a miniature scale.Once the designer has the initial vision in mind, it may be translated into a CAD (Computer Aided Design) model. Building the intricate design on the computer allows for a level of finesse and creation of detail that is impossible to achieve with a handmade model.

Printing

A 3D printer is then used to progress the digital design to a three dimensional model of wax or resin.

Casting

The model is embedded in plaster and vacuum injected with liquid metal to form the component parts.

Assembling

Here, the traditional skills of the master jeweller are utilised to build the final form of the design.

Setting

Fitting or “setting” the gemstones into the design is a highly skilled task performed by only the most experienced craftsmen. Each stone has to be set to perfectly enhance its natural beauty and secure its position for a lifetime and beyond.

Polishing

Many stages of polishing using buffs and brushes that are progressively more fine, right up to the final step called lapping. This ensures each piece achieves a breathtakingly gleaming finish.

Assessment

The final, most important step is to check everything under high magnification to verify it meets Nina’s exacting standards. Only then is this carefully crafted treasure ready to go home with you.

The information below is required for social login

LOG IN

Create New Account