How the diamond cutting process works

The diamond cutting process is how a rough stone is turned into a beautifully shaped and faceted gemstone, or in other words, a polished diamond.

The very important and complicated process of cutting and shaping raw diamonds requires the expert knowledge and skillful technique of qualified diamond experts, and of course the right equipment. Due to its extreme difficulty, every decision will either determine the value of the 4Cs or have an effect on the finished product.

One of the main reasons this process is so incredibly difficult, is that diamonds are one of the hardest materials on the planet. So, the only way they can be cut is with diamond bladed tools, or at least have an edge of diamond dust.

There are five steps when it comes to the cutting process. The planning phase, cleaving, bruting, polishing and inspecting. Here’s a more detailed breakdown.

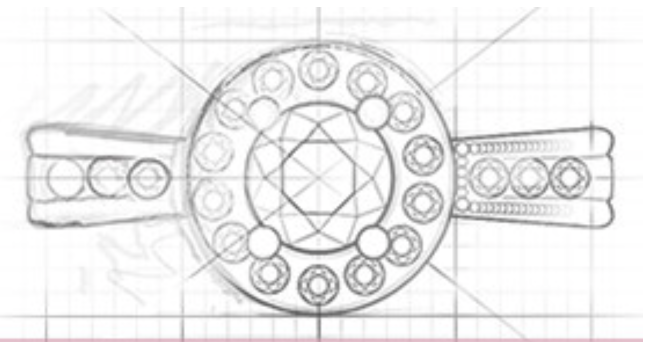

Step 1: Planning

Before diamond cutting even begins, the planning stage is when everything about the completed diamond is determined using a combination of expert knowledge and computer software to map out each diamond in the rough. Diamond cutters also evaluate any inclusions or flaws in the stone, determine carat weight, and ultimately decide if the finished diamond should be shaped with a brilliant cut or a step cut. Their goal is to create a finished product that maximizes the rough, without having too much waste in the process.

Before diamond cutting even begins, the planning stage is when everything about the completed diamond is determined using a combination of expert knowledge and computer software to map out each diamond in the rough. Diamond cutters also evaluate any inclusions or flaws in the stone, determine carat weight, and ultimately decide if the finished diamond should be shaped with a brilliant cut or a step cut. Their goal is to create a finished product that maximizes the rough, without having too much waste in the process.

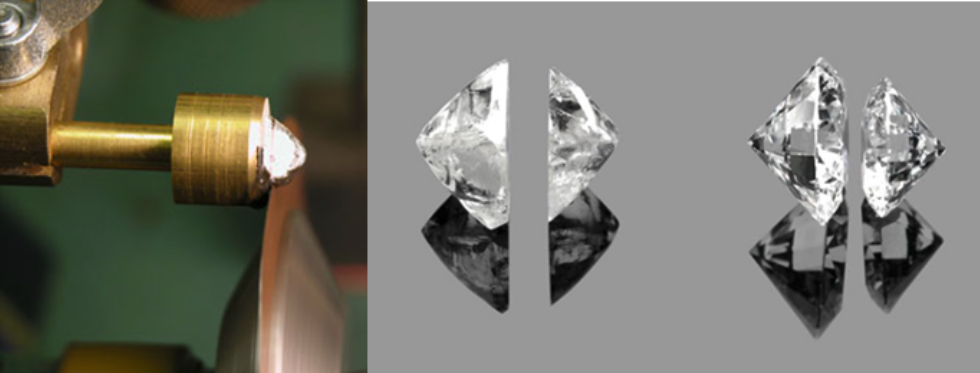

Step 2: Cleaving

The next step involves cleaving and splitting the diamonds in the rough so that they now become separate pieces. This is usually completed with mechanical saws by hand, or alternatively a machine with contactless lasers to ensure the diamond is in the best shape. Cutting through a 1-carat rough diamond can take anywhere between 4 to 8 hours, and it can take even longer if the saw hits a knot. While diamond cutting machines are highly accurate, cutting a diamond by hand remains a truly incredible piece of craft work.

The next step involves cleaving and splitting the diamonds in the rough so that they now become separate pieces. This is usually completed with mechanical saws by hand, or alternatively a machine with contactless lasers to ensure the diamond is in the best shape. Cutting through a 1-carat rough diamond can take anywhere between 4 to 8 hours, and it can take even longer if the saw hits a knot. While diamond cutting machines are highly accurate, cutting a diamond by hand remains a truly incredible piece of craft work.

Step 3: Bruting

Also known as girdling or rounding the roughs, bruting is where the rough diamonds are separated and turned into round stones. This process includes placing two cleaved stones on opposite sides of a spinning axle or lathe, before turning them in opposite directions. Then the two diamonds grind against each other during each revolution, which ultimately gives them a rough finish of a rounded shape.

Also known as girdling or rounding the roughs, bruting is where the rough diamonds are separated and turned into round stones. This process includes placing two cleaved stones on opposite sides of a spinning axle or lathe, before turning them in opposite directions. Then the two diamonds grind against each other during each revolution, which ultimately gives them a rough finish of a rounded shape.

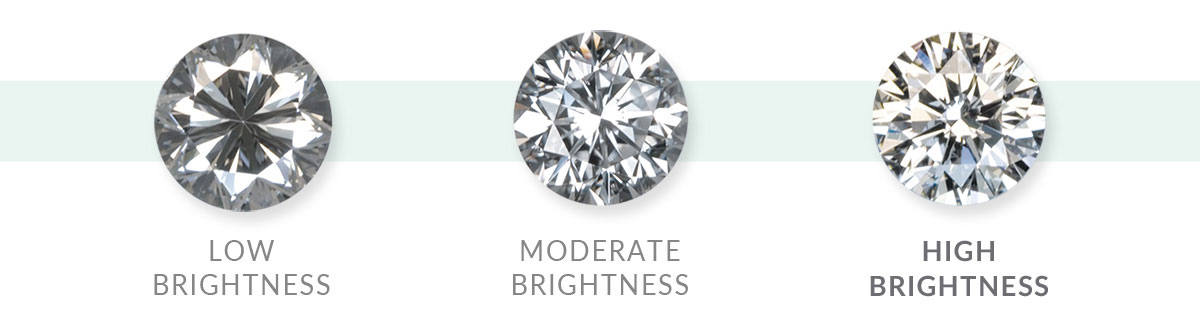

Step 4: Polishing

Once bruting has been completed, the rounded stones are then polished using a coarse diamond powder and a polishing wheel to carefully block and polish around the shape of the stone. This creates the flat and reflective surfaces which ultimately determines its brilliance as it becomes a completed diamond.

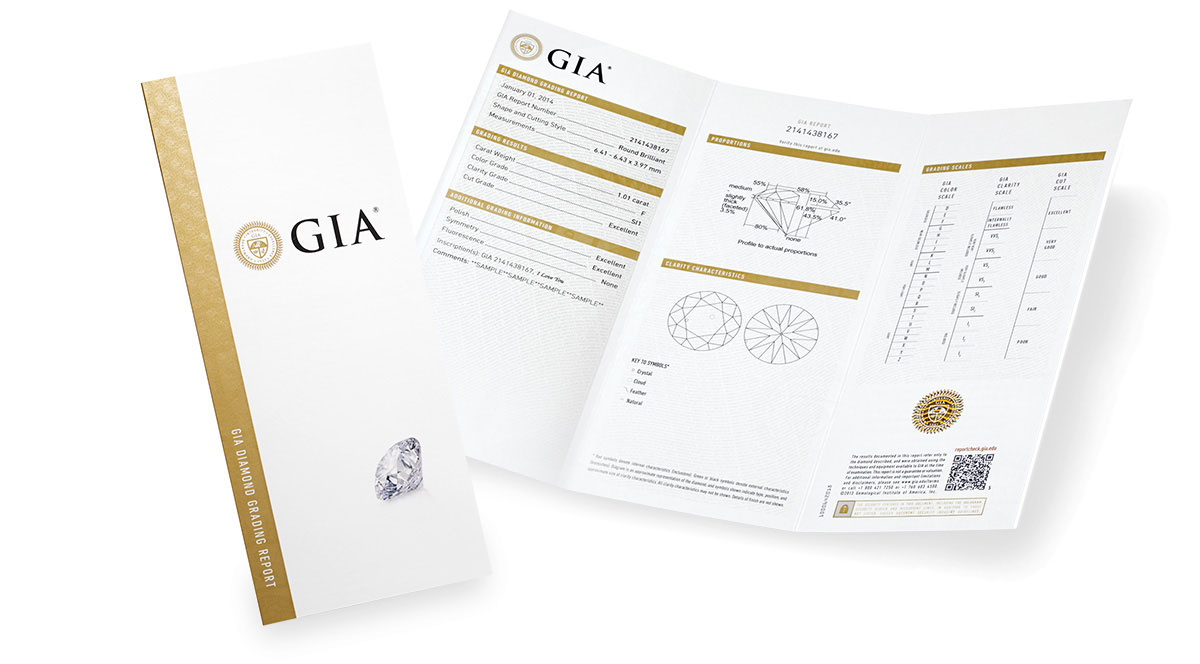

Step 5: Inspecting

Only then is this carefully crafted treasure ready to go home with you. During the final inspection, the diamond is cleaned thoroughly with acids before being checked under high magnification to verify it will meet the specifications and quality standards set out by the manufacturer, as well as Nina’s own exacting standards. As soon as the diamond is approved, it is then sent off to be officially graded and assigned its value.

After the diamond cutting

After the above steps of the cutting process are done, the finished diamond goes to a facility that independently reviews and grades diamonds.

They check and confirm all aspects of the diamond’s clarity, colour, carat weight, and cut grade including symmetry and polish. Once it has been certified, the diamond comes here to Nina’s where it will ultimately end up as a ring, earring, necklace, bracelet or another piece of jewellery that someone will choose to treasure for years to come.

Is GIA certification necessary?

A GIA grading report is highly desirable when purchasing a loose diamond over a certain size, so you can quickly and easily check that you are getting what you paid for.

A GIA grading report is highly desirable when purchasing a loose diamond over a certain size, so you can quickly and easily check that you are getting what you paid for.

Here at Nina’s, we use GIA to grade the best of our diamonds as they are fair, neutral, and are trusted by jewellers worldwide to accurately and consistently certify diamonds. Even though it is possible to buy diamonds without grading or certification, Nina’s recommends either choosing a correctly certified stone like this, or dealing with a trusted, GIA certified diamond specialist like Nina’s where you can be guaranteed of quality and transparency in your purchase.

Nina’s craftspersons & master jewellers

While Nina’s don't have in-house diamond cutters, Argyle certainly do. They take great care in the planning and shaping of their Argyle tender stones, and work with the finest lapidaries in the world to shape these once in a lifetime diamonds.

Nina's has been analysing, buying and crafting jewellery from diamonds in Western Australia for over 50 years from both their Dunsborough workshop and their Kununurra showroom, just two hours from the iconic Argyle diamond mine.

Offering only natural, ethically-sourced diamonds of the highest quality, Nina's experts hand-select for each piece of jewellery they create, and every customer’s individual needs.

View their fine selection of diamond rings, diamond pendants, diamond earrings and loose diamond collection.

The information below is required for social login

LOG IN

Create New Account